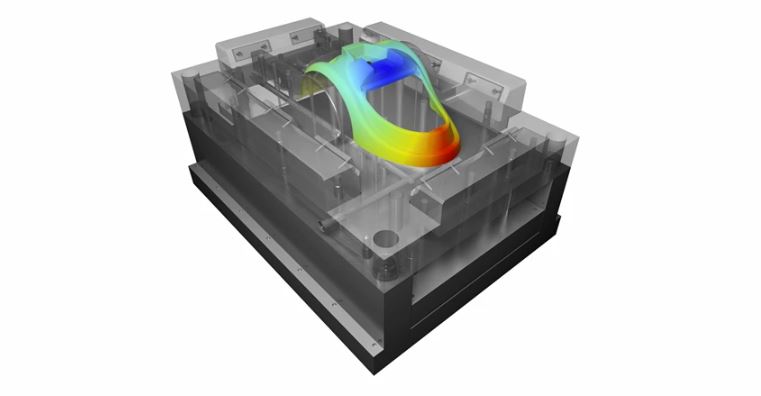

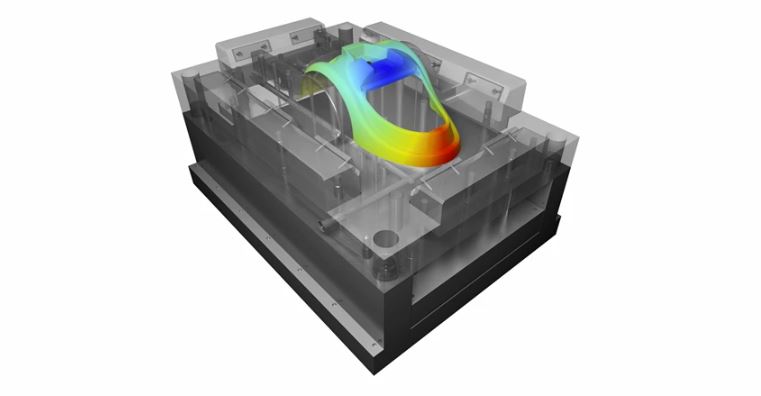

Formfyllnadsanalys

Vi kan vi hjälpa till med formfyllnadsanalyser och ge feedback på hur din detalj kan förbättras för att skapa rätt förutsättningar för en så smidig formsprutningsprocess som möjligt.

Man kan spara mycket onödiga kostnader genom att göra en grundläggande förstudie på hur formsprutningsprocessen kommer se ut innan man producerar ett verktyg för en ny eller ändrar en befintlig produkt.

Fördelar

Att göra en formfyllnadsanalys är ett väldigt bra sätt för att optimera ett verktyg innan man påbörjar produktionen av verktyget. Detta möjliggör att man kan nå tänkt resultat på kortare tid genom:

- att få insikt i produktens egenskapsprofil och vilka processparametrar som är mest väsentliga under optimeringsarbetet,

- möjligheten att bygga en robustare produkt med ökat processfönster,

- men också vanligtvis lägre utvecklingskostnader.

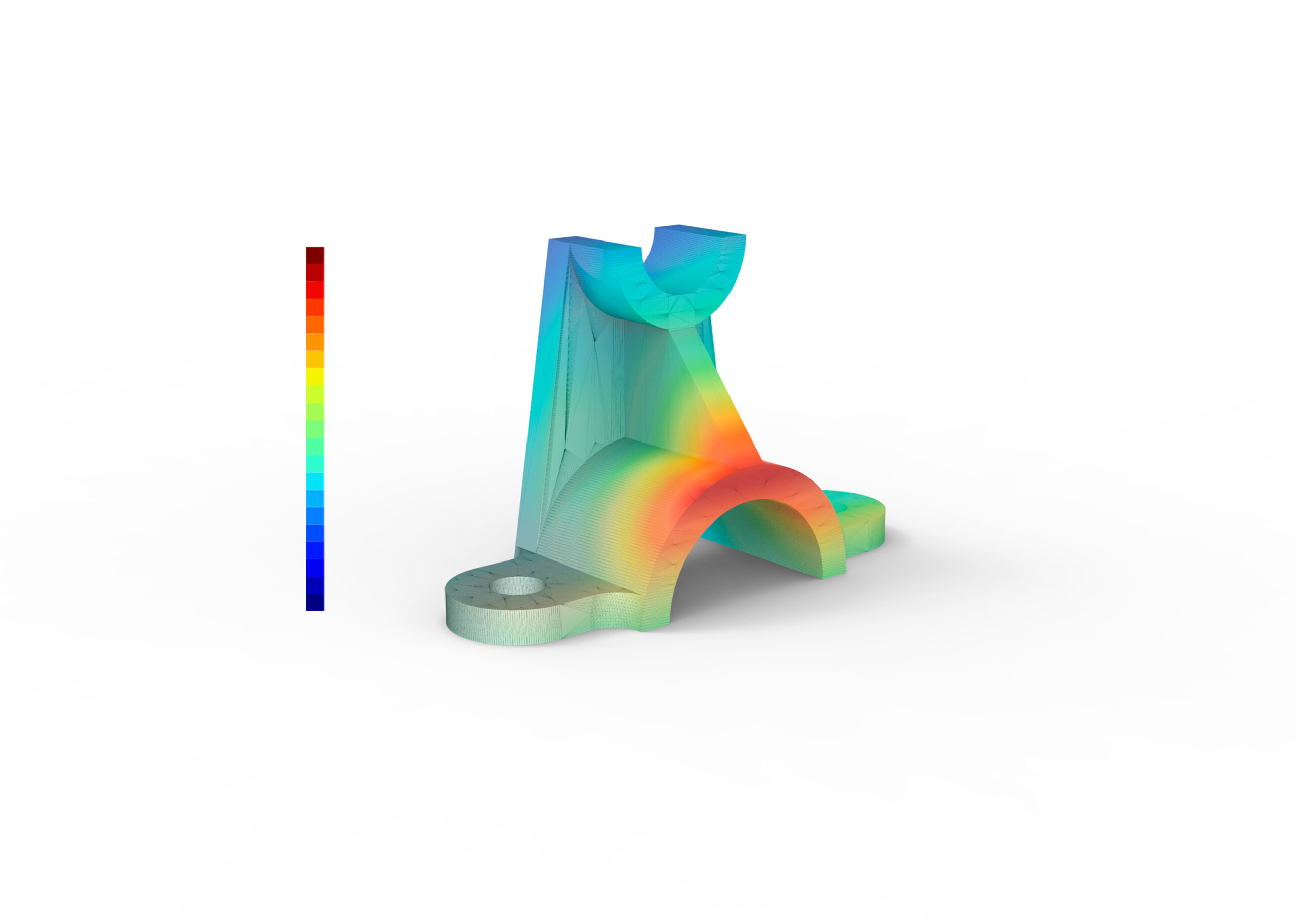

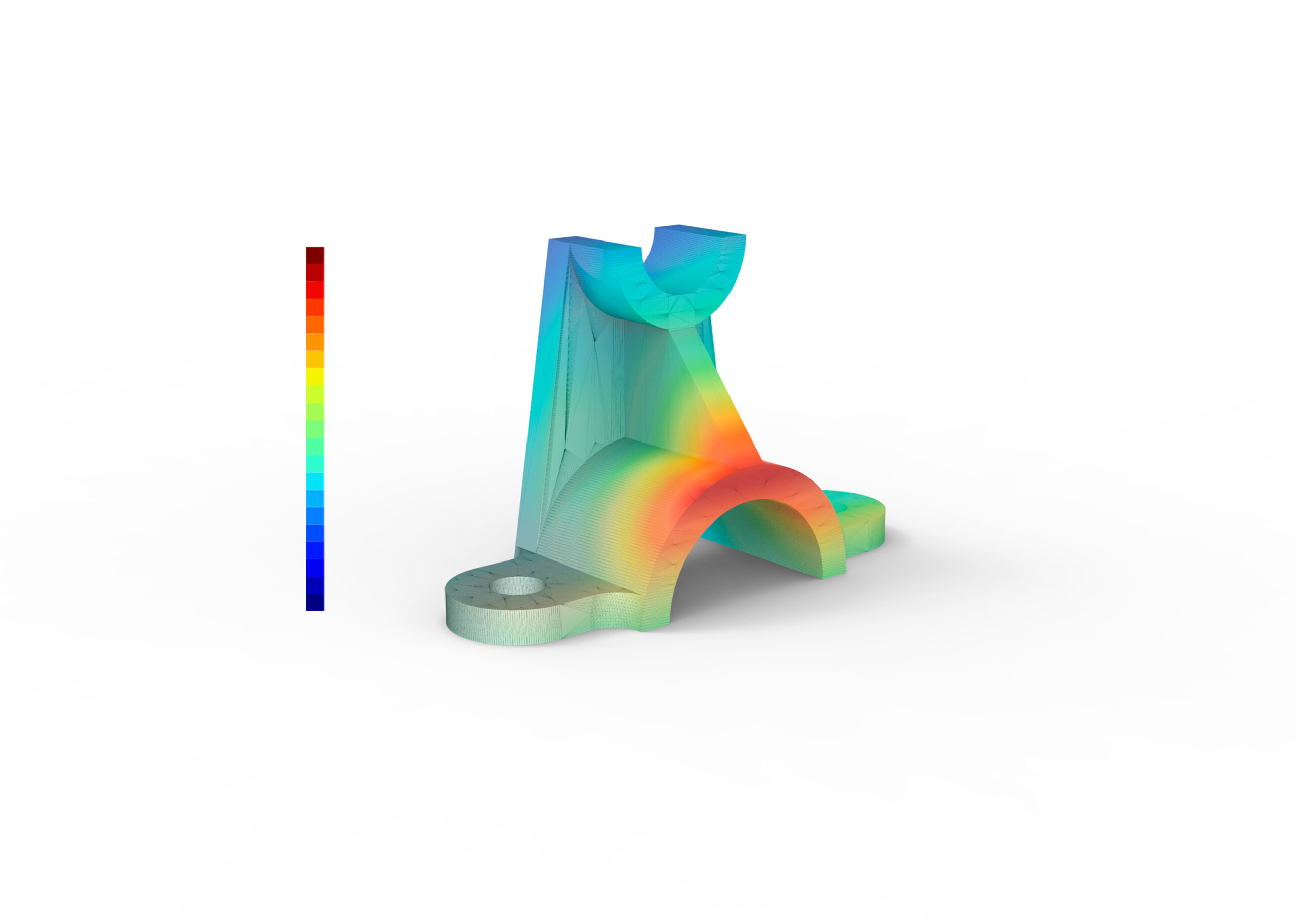

Simuleringsprogram

För att kunna förbättra produkten i ett så tidigt stadie som möjligt har vi tillgång till två olika simuleringsprogam:

- Moldflow

- Moldex3D